NEXUM Designer

With the NEXUM®-PDC Designer, complex factory controls are set up using a graphical layout interface. Kompliziert? Natürlich nicht. Geradezu spielerisch einfach.

Without programming knowledge, entire production plants can be parameterised - consisting of electronic tools, programmable logic controllers, ID systems and all other necessary elements.

After the initial commissioning, the plant operator is given a tool with which he can design an entire production line without programming knowledge, adapt it to the needs of production and make changes at short notice independently.

You have your plant in your own hands

In the past, every small change to a parameterisation system required an expert to be called in, or even to travel to the site in person, in order to programme every change, no matter how small, in terms of both time and personnel. The NEXUM PDA Designer now enables trained planners and plant operators to

- to carry out all modifications

- themselves

- in a very short time and

- without great effort.

The multi-language capability, also for RTL languages or your Asian partners, also makes it easy to use NEXUM-BDE in an international context.

We need to talk to each other

The unit-specific software libraries are a central element. An individual interface is created for each hardware controlled or recorded by NEXUM®-BDE. Thus, all components with data interface can be integrated. Without much effort, of course. And yes: Really all components on the market with data interface.

Due to the modular software concept, all components of an automated production can be addressed, such as for example

- Screw systems

- Welding robot

- Programmable logic controllers (PLC)

- Bus systems such as Interbus, Profibus and Profinet

- Coupling with the help of TCP-IP

- FTP client and server systems

- Rework systems with worker guidance

- Optical signalling devices, such as dome lights

- Receipt printer

- Scanners and RFID systems (e.g. LEGIC readers)

The entire production at a glance

Factory location - production line - work sequence - conveyor technology - PLC - controlled tool systems - hand scanner: These are the dimensions of complex manufacturing. Once provided with the appropriate template, NEXUM®-BDE Designer can be used to design the entire plant from the production cycle to the final inspection. The designer shapes all the individual parts into a functioning unit. Once set up and stored in the database, only the corresponding parameterisation needs to be activated in the station. Lengthy programming work in the plant? Production interruptions during changes? Insecure and dissatisfied employees? Not with NEXUM Designer! Simply start the execututer and continue production.

Factory location - production line - work sequence - conveyor technology - PLC - controlled tool systems - hand scanner: These are the dimensions of complex manufacturing. Once provided with the appropriate template, NEXUM®-BDE Designer can be used to design the entire plant from the production cycle to the final inspection. The designer shapes all the individual parts into a functioning unit. Once set up and stored in the database, only the corresponding parameterisation needs to be activated in the station. Lengthy programming work in the plant? Production interruptions during changes? Insecure and dissatisfied employees? Not with NEXUM Designer! Simply start the execututer and continue production.

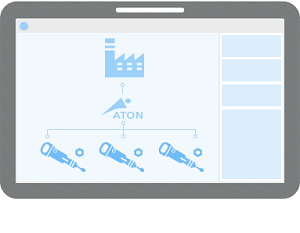

From the hall to the bolting programme

The factory always represents the top element. Then follows the hall, a number of production lines, many cycles as well as numerous communication partners.

The factory always represents the top element. Then follows the hall, a number of production lines, many cycles as well as numerous communication partners.

Each element receives its unique key in the corresponding level. This hierarchy is defined in an F-Key-Picture, quasi a template. In this way, each individual component of a production is given its own unique key with which it can be individually addressed. Unclear about the parameterisation? Not with the NEXUM®-BDE Designer! Thanks to NEXUM®-BDE Designer, ambiguities - at least in your company - are a thing of the past.

From the model to the smallest screw

Every product has a multitude of assemblies, parts and attachment points. Here, the P-Key Picture brings structure to the structure. Each assembly, each part, each screw is given a unique key that can later be assigned to an equally uniquely named tool. This results in the work plan, which is graphically animated with NEXUM®-BDE Executer in the station and guides the workers. The recorded work results, which form the basis for downstream quality control loops and statistical evaluations, are just as clear.

Every product has a multitude of assemblies, parts and attachment points. Here, the P-Key Picture brings structure to the structure. Each assembly, each part, each screw is given a unique key that can later be assigned to an equally uniquely named tool. This results in the work plan, which is graphically animated with NEXUM®-BDE Executer in the station and guides the workers. The recorded work results, which form the basis for downstream quality control loops and statistical evaluations, are just as clear.

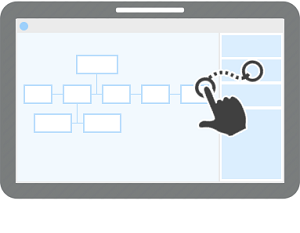

Carry out changes yourself with "drag and drop

Every production plant experiences modifications in the course of its operation. The model receives an upgrade, a new tool is installed or even the material composition of a screw is new - changes are already necessary.

How are these changes implemented? By reprogramming the software used? By the cost-intensive commissioning of an external service provider who implements these changes with his expert knowledge? By using your own staff, who have to familiarise themselves with the subject at great expense?

Fortunately, this is not necessary thanks to NEXUM®-BDE Designer with its tried and tested drag and drop technology! Save time and money ... and build up your own know-how in your company at the same time. We will be happy to support you!

Every production plant experiences modifications in the course of its operation. The model receives an upgrade, a new tool is installed or even the material composition of a screw is new - changes are already necessary.

How are these changes implemented? By reprogramming the software used? By the cost-intensive commissioning of an external service provider who implements these changes with his expert knowledge? By using your own staff, who have to familiarise themselves with the subject at great expense?

Fortunately, this is not necessary thanks to NEXUM®-BDE Designer with its tried and tested drag and drop technology! Save time and money ... and build up your own know-how in your company at the same time. We will be happy to support you!

With NEXUM®-BDE Designer ...

- trained employees carry out changes in the process themselves,

- relocate or replace tools with others,

- run the process with a different programme or

- have the assembly of a part carried out at a different location.

Revision management

A horror scenario from the worst nightmare that surely every planner, plant operator and worker fears: A change made to the production system leads to a production stop, despite extensive tests having been carried out beforehand - nothing works any more, the disaster case has occurred! Stop! Your company uses the NEXUM®-BDE Designer? Then you won't wake up from this nightmare drenched in sweat, because thanks to NEXUM®-BDE Designer you can sit back and relax even in this situation. Why?

A horror scenario from the worst nightmare that surely every planner, plant operator and worker fears: A change made to the production system leads to a production stop, despite extensive tests having been carried out beforehand - nothing works any more, the disaster case has occurred! Stop! Your company uses the NEXUM®-BDE Designer? Then you won't wake up from this nightmare drenched in sweat, because thanks to NEXUM®-BDE Designer you can sit back and relax even in this situation. Why?

A sophisticated revision management of the NEXUM®-BDE Designer ensures that the desired, original state of the plant is restored within seconds with just a few mouse clicks. Without complications. Simple. Safe.

NEXUM Designer: Design your production

NEXUM Designer: Design your production