NEXUM Executer - for your uninterrupted and failure-free production

The NEXUM Executer - a new dimension of graphical process control in automated production. Integration of higher-level factory control systems, conveyor technology, screwdrivers and welding systems from all manufacturers thanks to modular interface programming.

Graphical interfaces and multilingual work instructions ensure reliable execution of all process instructions in every production cycle.

The Executer is the controller for interruption- and failure-free production.

Your benefits at a glance

The NEXUM Executer offers multilingual graphical worker guidance and is used in work cycles and rework. Thanks to its modular interfaces, it integrates factory control systems, conveyor technology, screwdrivers and welding systems from all manufacturers and ensures uninterrupted and failure-free production.

Different settings can be made for each station PC, which are stored centrally or in the NEXUM master data in the database. A detailed role-rights concept regulates on an individual basis which employee is assigned which rights. For example, if the login is carried out with worker rights, the administration buttons are not visible.

The primary tasks of the executor can be summarised as follows:

- Guidance of the employee in the work cycle with the aid of a type-related graphic. A separate display is available for each workpiece type

- Respond to external events such as control signals from a PLC, evaluation of a scan, etc.

- Comparison of transmitted information with the higher-level factory control system

- Control of tools according to type in combination with display of the relevant work instructions

- Acquisition of quality data transmitted from a tool control system

- Transmission of the work result, e.g. to a PLC or to a higher-level factory control system.

The control center on site

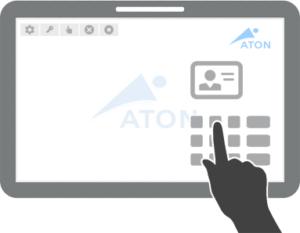

The user has an overview of all process steps in the production cycle on touch-screen interfaces.

The integrated touch keyboard enables secure input of user information even when wearing gloves.

The user has an overview of all process steps in the production cycle on touch-screen interfaces.

The integrated touch keyboard enables secure input of user information even when wearing gloves.

Identification of the worker by electronic badge readers is possible, as is the definition of different user rights for deciding who is allowed to carry out which operating steps.

Visualisation

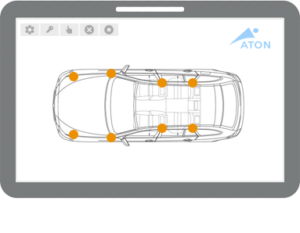

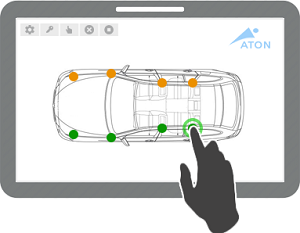

Process graphics show what has to be done and in what order. With the help of specific interfaces, the connected tool is controlled according to the work plan, the measuring point is animated and the employee is informed.

Process graphics show what has to be done and in what order. With the help of specific interfaces, the connected tool is controlled according to the work plan, the measuring point is animated and the employee is informed.

When the work is completed, the PC sends a completion message to the conveyor system, which then conveys the workpiece out. Each worker guidance for a production - no matter how many station PCs are running - is parameterised in the Designer in this way.

Final inspection

With the attentive eye of the responsible employee and with the help of the Executer surface control, errors as well as necessary residual work can be detected during the run through the production line and, depending on the characteristics, reworked.

With the attentive eye of the responsible employee and with the help of the Executer surface control, errors as well as necessary residual work can be detected during the run through the production line and, depending on the characteristics, reworked.

Scratches, excessive gaps - whatever reduces the quality - in the rework the error is corrected and acknowledged on the PC.

Status control

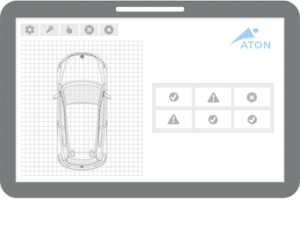

It is possible to see at a glance which step is next. The employee on site thus always knows the status of the system.

It is possible to see at a glance which step is next. The employee on site thus always knows the status of the system.

Quality always under observation

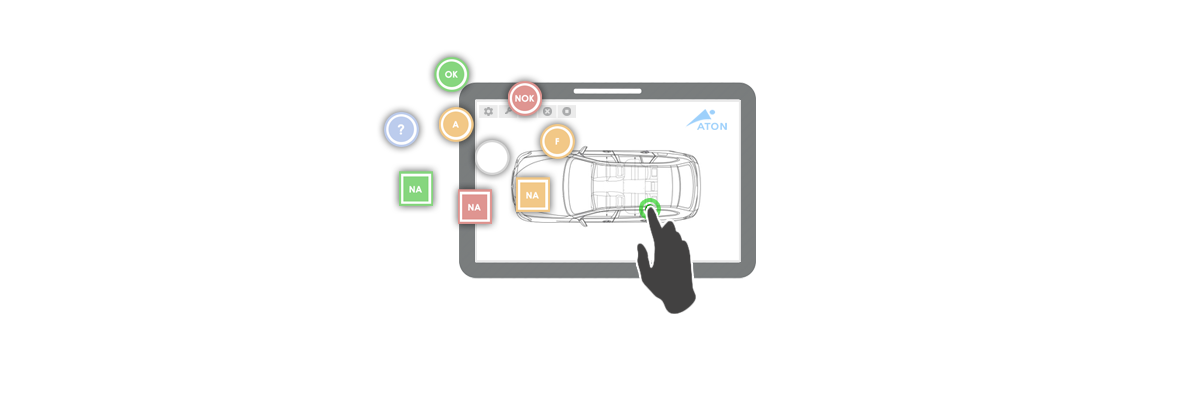

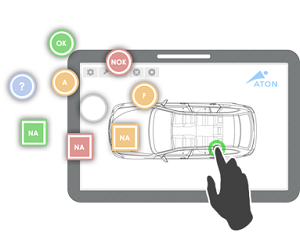

Why is this screw result NOK? Touching the measuring point provides the explanation. The point is red, although everything is OK? An OK acknowledgement is possible on the spot. This has to be approved by the supervisor? No problem! The supervisor logs in electronically with his plant ID card via a card reader and acts according to his parameterised authorisation. Whoever is allowed to do something; it can be set on the execututer.

Why is this screw result NOK? Touching the measuring point provides the explanation. The point is red, although everything is OK? An OK acknowledgement is possible on the spot. This has to be approved by the supervisor? No problem! The supervisor logs in electronically with his plant ID card via a card reader and acts according to his parameterised authorisation. Whoever is allowed to do something; it can be set on the execututer.

In addition to manual quality control, log files that are indispensable for fault analysis record event, error and warning messages. Various, sophisticated error levels support plant operators in troubleshooting. The level of detail can be set during parameterisation of the individual plant components in NEXUM®-BDE Designer as well as during operation in NEXUM®-BDE Executer.

NEXUM®-BDE Executer and your workers: A perfect team, a common goal. Simple production. Uninterrupted.

NEXUM Executer. The reference.

NEXUM Executer. The reference.