Reference projects: Automotive engineering, logistics and (high) technology

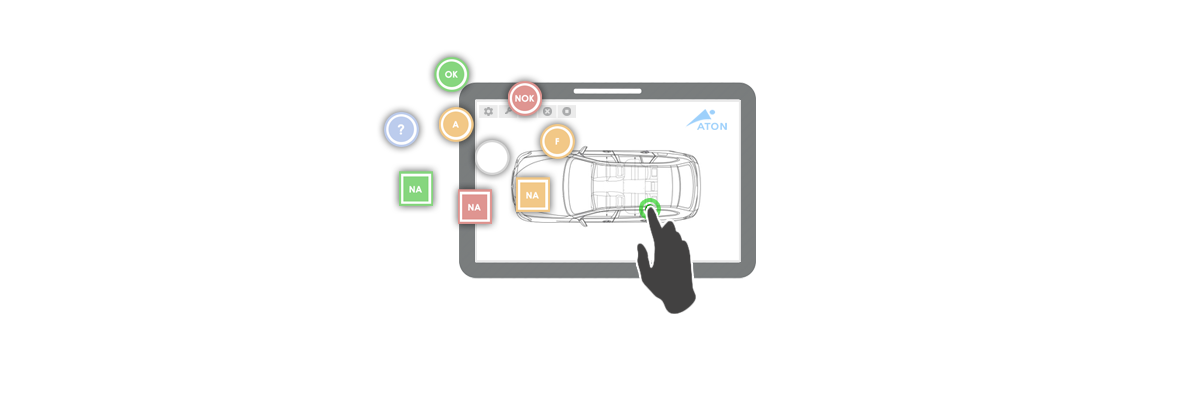

ATON's software is used extremely successfully by our customers. In automotive engineering. In logistics. In (high) technology.

Our custumers use our expertise in software development where perfection, effectiveness and efficiency are necessary.

Programmed in Germany. In use worldwide.

Software development reference projects

Software development reference projects